3M™ High Flow Series Retrofit Filter Cartridge HFR60PPA70D, 60 in, 70 umABS, Nitrile , 1/Case

Solventum’s Purification and Filtration Business is now a part of Thermo Fisher Scientific. Drinking Water Filtration remains with Solventum. For more information, please visit here.

About the product

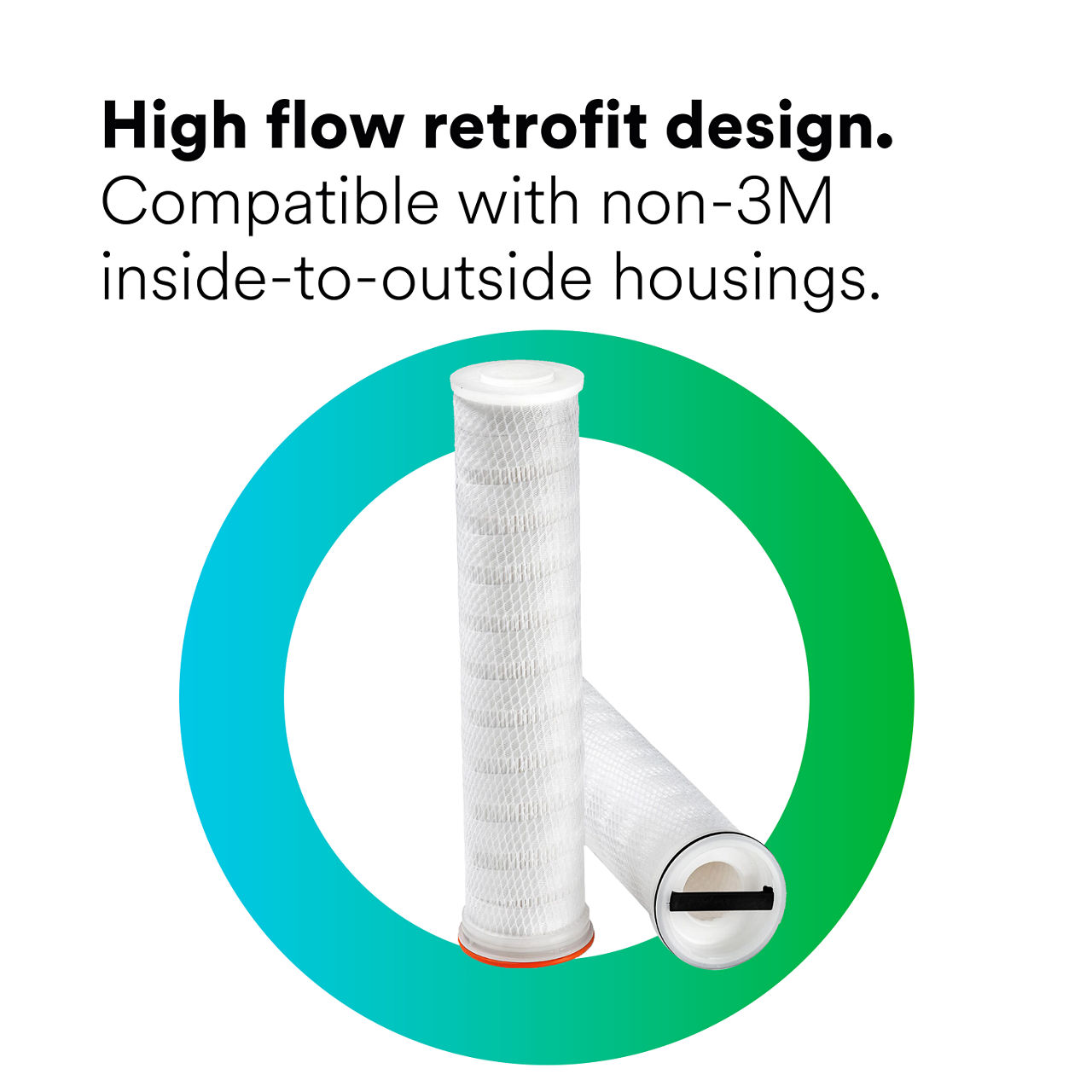

Offering a high inside-to-outside flow capacity, 3M™ High Flow HFR Series Retrofit Filter Cartridges have an absolute retention rating to help remove particles and other contaminants from water, industrial chemicals and liquid food and beverages*. Using 3M’s multi-layer media, these high flow retrofit filters fit into third-party inside-to-outside flow housings and help reduce operating costs.

Product details

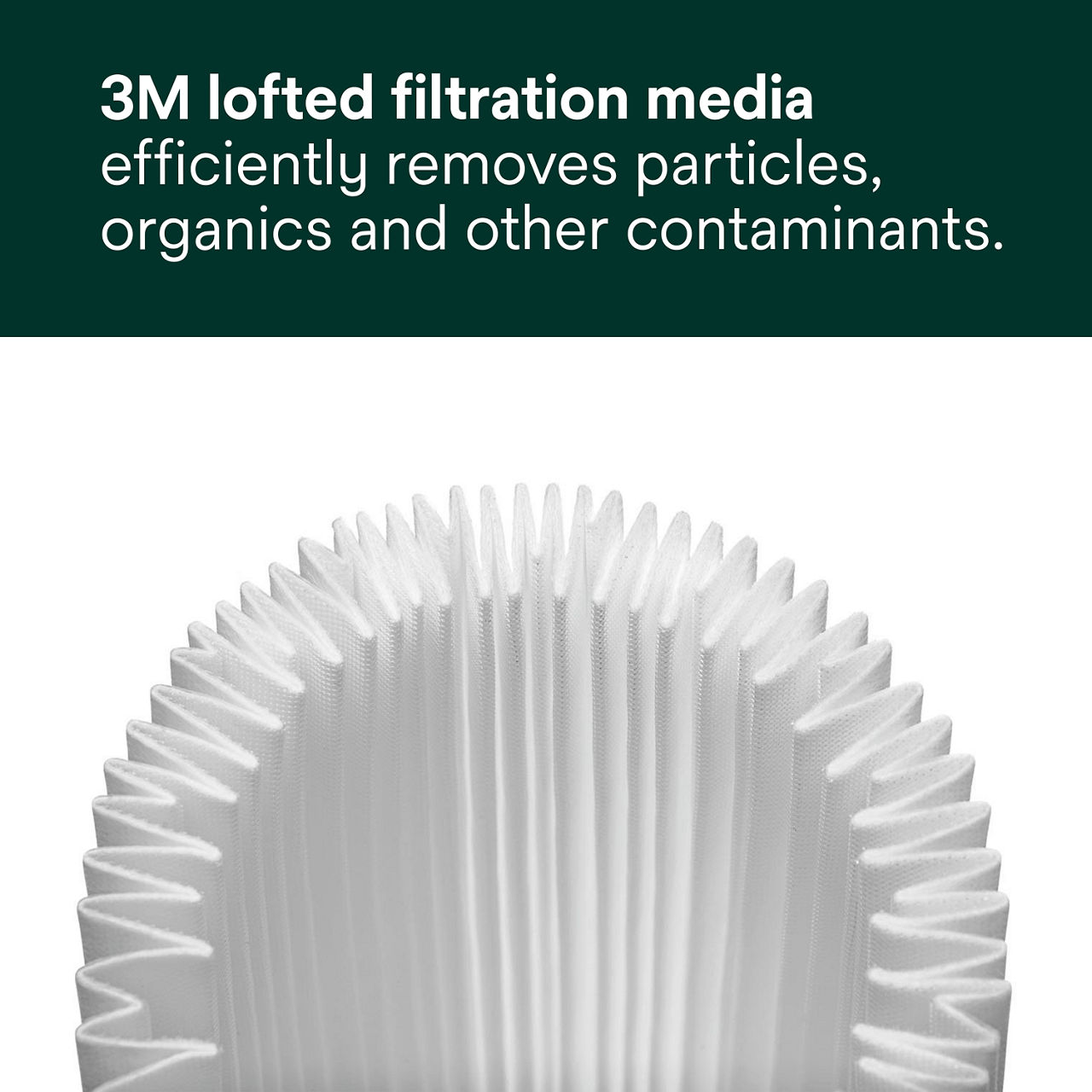

Constructed of a polypropylene microfiber media, 3Mpleated filter cartridges have a uniform matrix, effluent quality and a high particle removal efficiency throughout the filter life. The lofted media design helps prevent premature blinding of the filter’s outer surface, promoting fuller utilisation of the media, resulting in an optimum combination of particle removal efficiency and contaminant holding capability.

Ideal for a wide range of industrial filtration applications, the 3M™ High Flow HFR Series Microfiber Filter Media is optimised for use in process water applications containing organic contaminants, as well as particulates. 3M™ High Flow HFR Series Filter Cartridges are available in 6 distinct absolute micron ratings ranging from 5 to 100 microns and 3 integral lengths, 20, 40 and 60 inches, to fit third-party filter housings. All filter components are thermally bonded to provide a structurally integral filter. No resins, binders or adhesives are used in the manufacturing process.

*For details related to specific use conditions or limitations for food contact applications, please contact your 3M representative for more information.

- Advanced Pleat Technology (APT) provides long filter life by increasing the usable filtration area

- 3M lofted microfiber filtration media offers high particle and organic removal efficiencies, high contaminant capacity and extended service life

- Absolute-rated filters provide consistent and reproducible contaminant reduction

- Wide ergonomic handle provides comfortable grip during change-outs, even when wearing gloves

- Single filter seal point reduces chance of fluid bypass

- Designed to retrofit into existing third-party inside-to-outside flow housings

- Extensive food contact compliance - For details related to specific use conditions or limitations for food contact applications, please contact your 3M Representative for more information

Suggested Applications

- Food & Beverage

- Utility water

- Parts washing (OEM)

- Desalination

- Pre-RO water

- Condensing water filtration

- Process waters

- Boiler feed water

- Injection and produced waters

- Ground / reclaimed / waste waters

- Refining (amine sweetening, final product)

- Coolants

Product specifications

| Industries |

Industries

Chemical manufacturing,Food & beverage manufacturing,Industrial water,Manufacturing,Microelectronics,Steam & power generation |

| Product Form |

Product Form

Cartridge |

| OverallDiameterMetric |

OverallDiameterMetric

15.24 cm |

| OverallDiameterImperial |

OverallDiameterImperial

6 in |

| Grade |

Grade

HFR |

| Micron Rating (Absolute) |

Micron Rating (Absolute)

70 absolute, @ 99.9% |

| Product Series |

Product Series

High Flow |

| Flow Rate (Metric) |

Flow Rate (Metric)

100 m³/hr |

| Flow Rate (Imperial) |

Flow Rate (Imperial)

440.335 gal/min |

| OverallLengthMetric |

OverallLengthMetric

152.4 cm |

| Overall Length (Imperial) |

Overall Length (Imperial)

60 in |

| Product Type |

Product Type

Pleated Non-Woven Media |

| Category name |

Category name

Pleated Membrane Cartridges |

| Filter Type |

Filter Type

Surface |

| FilterTechnology |

FilterTechnology

Non-woven |

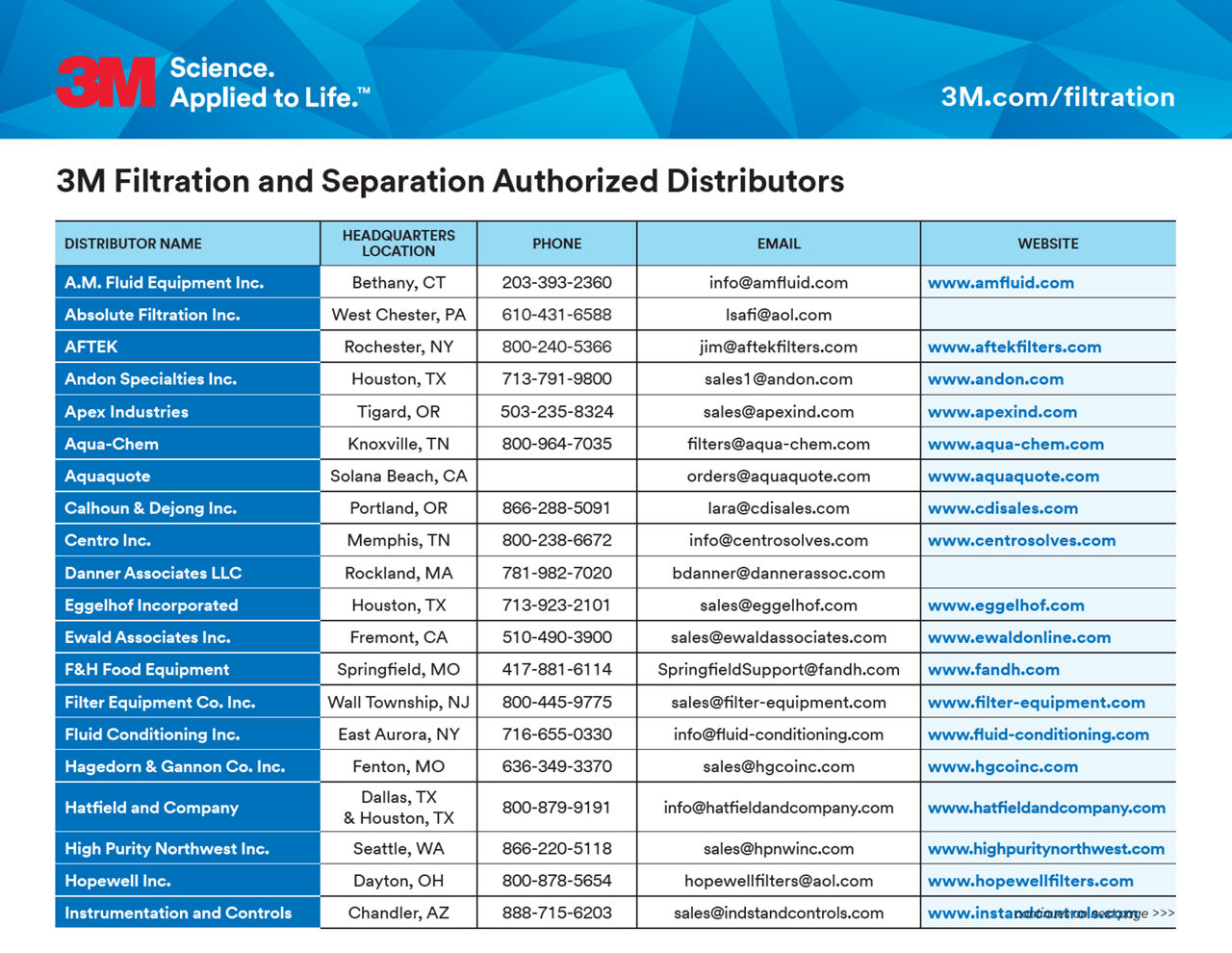

Distributors

| Solventum Filtration Distributor | Headquarter Location | Contact | Contact Email | Contact Phone | Website |

|---|---|---|---|---|---|

| A.M. Fluid Equipment, Inc. | Bethany, CT | Ross Nelson | ross.nelson@amfe-filter.com | 203-393-2360 | https://amfluid.com |

| BMB Filtration | Jacksonville, FL | Butch Lee | butch@bmbent.net | 904-880-7925 | https://bmbfiltration.com/ |

| Calhoun & De Jong, Inc. | Portland, OR; Seattle, WA | Ed Calhoun | ed@cdisales.com | 1-866-288-5091 | https://cdisales.com |

| C.C. Day Company | Minneapolis, MN | Chris Magnine | cmagnine@ccday.com | 763-350-3415 | https://ccday.com |

| Danner Associates | Rockland, MA | Brian Danner | bdanner@dannerassoc.com | 781-982-7020 | https://www.dannerassociates.com/ |

| Eggelhof Incorporated | Houston, TX | Ben Ellis | bellis@eggelhof.com | 832-301-0966 | https://www.eggelhof.com/ |

| Enpro Inc. | Addison, IL | John Burnett | john_burnett@enproinc.com | 314-378-6829 | https://enpro.com/ |

| Filter Equipment Co., Inc. | Wall, NJ | Scott Groh | scgroh@filter-equipment.com | 908-216-3879 | http://www.filter-equipment.com/ |

| George Yardley Company | Santa Ana, CA | Rob Yardley | rob@georgeyardley.com | 714-241-7700 | https://georgeyardley.com/ |

| Hagedorn & Gannon Co., Inc. | Fenton, MO | Ty Van Buren | tvanburen@hgcoinc.com | 636-349-3370 | https://www.hgcoinc.com/ |

| Hatfield and Company, Inc. | Rockwall, TX | Jason Reed | jreed@hatfieldandcompany.com | 832-671-9719 | https://www.hatfieldandcompany.com/ |

| MSC Industrial Supply | Melville, NY | Jim Keating | jim.keating@mscdirect.com | 440-656-8042 | https://www.mscdirect.com/ |

| Pack-n-Tape | Lafayette, CO | Lisa Higginbotham | lhigginbotham@pack-n-tape.com | 888-262-1988 | https://pack-n-tape.com/ |

| Rawson Industrial Controls | Daphne, AL | Mike Mercier | mike.mercier@rawsonlp.com | 404-281-5704 | https://rawsonicd.com/ |

| Ryan Herco Flow Solutions | Santa Ana, CA | Bob Lucas | blucas@rhfs.com | 612-889-9248 | https://www.rhfs.com/ |

| SunSource | Addison, IL | Tom Lisy | tom.lisy@sunsrce.com | 440-935-4994 | https://www.sun-source.com/ |